A Quick Guide to Hazardous Waste Container Marking

Hazardous waste management is an essential responsibility for businesses that generate or handle potentially dangerous materials. One critical aspect of this process is clearly and accurately marking hazardous waste containers. Labeling not only protects individuals and prevents environmental hazards but also ensures compliance with legal standards. This quick guide to hazardous waste container marking will explain how to stay safe and comply with federal and local requirements set by the Environmental Protection Agency.

Understanding Hazardous Waste Containers

Hazardous waste containers store materials that pose risks to human health and safety or to the environment. These containers vary in size, composition, and purpose, depending on the type of waste they hold. For example, some are suitable for corrosive liquids, while others may store flammable solids. Ensuring the container is appropriate for its contents is the first step in maintaining safety.

Why Mark Containers?

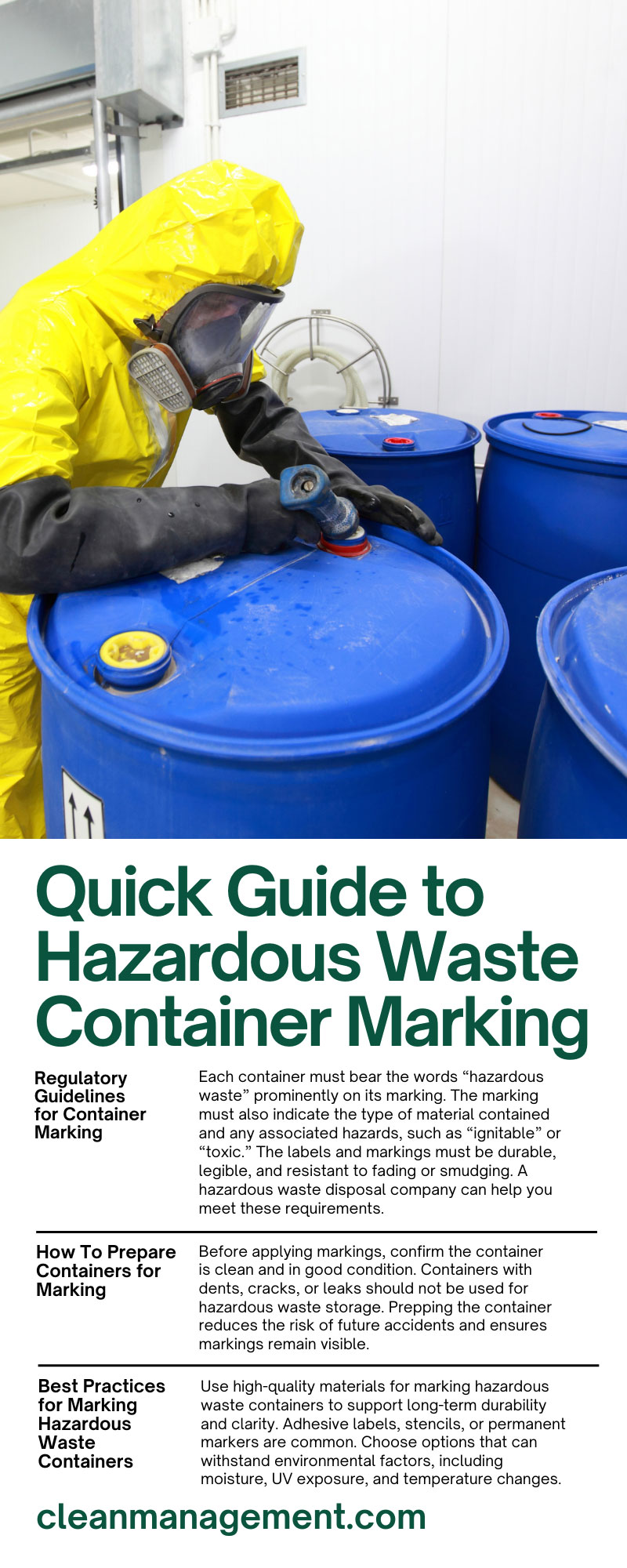

Marking hazardous waste containers is a legal obligation. Regulatory agencies, such as the Environmental Protection Agency (EPA), have outlined guidelines for hazardous waste labeling under the Resource Conservation and Recovery Act (RCRA). Failing to comply with these guidelines can result in penalties or operational disruptions.

Labeling containers with hazardous substances benefits everyone involved in handling and transportation. Clear labels ensure that employees, transporters, and emergency responders can identify the type of waste and the associated risks. This knowledge minimizes the likelihood of accidents, spills, or exposure to harmful substances.

[image a]

Information on the Label

To adhere to EPA regulations and ensure safety, hazardous waste container markings must clearly state the words “Hazardous Waste” and display a description of the waste. Additionally, it should include information about the generator of the waste and the date the accumulation started.

The label must also display hazard warnings, such as whether the material is flammable, corrosive, toxic, or reactive. Using pictograms or symbols to indicate the risks can further enhance clarity, especially for those with language barriers. Detailed and accurate information helps everyone handle these materials responsibly.

The Difference Between Marking and Labeling

Although marking and labeling are used interchangeably, they serve different purposes in hazardous waste management. Marking typically refers to large, permanent identifiers on the exterior of a container. They provide information about the contents, such as hazard type and waste characterization.

Labeling, however, often involves attaching detailed information to the container, including the material safety data sheet (MSDS) or transport instructions. Both marking and labeling work together to communicate the contents of hazardous waste containers.

Regulatory Guidelines for Container Marking

Each container must bear the words “hazardous waste” prominently on its marking. The marking must also indicate the type of material contained and any associated hazards, such as “ignitable” or “toxic.” The labels and markings must be durable, legible, and resistant to fading or smudging. A hazardous waste disposal company can help you meet these requirements.

How To Prepare Containers for Marking

Before applying markings, confirm the container is clean and in good condition. Containers with dents, cracks, or leaks should not be used for hazardous waste storage. Prepping the container reduces the risk of future accidents and ensures markings remain visible.

Use a flat, smooth surface on the container for markings. This guarantees that information is legible and easily identifiable. Apply coatings or paints for corrosion resistance before any markings.

Best Practices for Marking Hazardous Waste Containers

Use high-quality materials for marking hazardous waste containers to support long-term durability and clarity. Adhesive labels, stencils, or permanent markers are common. Choose options that can withstand environmental factors, including moisture, UV exposure, and temperature changes.

Position markings in a location that remains visible during storage, handling, and transport. Avoid placing markings on areas that may become obscured, such as on the bottom of containers. Regularly inspect containers and reapply labels if they show signs of wear or damage.

Common Mistakes To Avoid

[image b]

While marking hazardous waste containers may seem straightforward, making errors can have serious consequences. Using vague or unclear labels that fail to identify the nature of the waste is a big mistake. Another issue arises when markings fade or become illegible due to poor-quality materials or improper placement.

Overlooking the importance of maintaining consistent markings across all containers is another error. Failing to follow up with regular audits of containers and their markings can result in costly non-compliance penalties. Avoiding these mistakes requires attention to detail and adherence to established best practices.

Training Employees on Marking Practices

Training employees on hazardous waste container marking is essential for compliance and safety across your organization. Staff should understand the legal requirements and practical procedures for marking containers. This includes understanding how to recognize markings and report deficiencies.

Providing hands-on training sessions or instructional materials can improve employee compliance. Encourage job-specific training for different roles, whether for waste management teams, administrative staff, or transport professionals. Trained employees are a company’s first line of defense in maintaining safety.

The Role of Technology in Marking Containers

Advances in technology are helping business leaders streamline the container marking process. Many organizations use digital tools to create standardized label templates for the sake of consistent formatting and accuracy. Barcode systems allow for the tracking of hazardous materials throughout their lifecycle.

Furthermore, software solutions that integrate with regulatory databases can help professionals stay on top of legal requirements. These innovations reduce the risk of human error and enhance operational efficiency. Investing in technology is a step toward better hazardous waste management practices.

Regular Audits Support Compliance

Routine audits play a role in creating hazardous waste container markings. These audits involve examining the condition of containers, verifying the accuracy of markings, and updating records as necessary. Regular reviews of your practices offer valuable insights for correcting errors before they escalate.

Audits should extend beyond container markings to include the waste management process. Your organization’s approach will remain compliant and environmentally responsible. Partnering with an external consultant or industry expert can improve your audits.

Moving Toward Sustainability in Hazardous Waste Management

Sustainability is an integral part of hazardous waste management. Business leaders are finding new ways to reduce waste generation and promote environmentally responsible practices. Accurate container marking supports sustainability goals by reducing the risk of mismanaging hazardous materials.

Hazardous waste container marking encourages safe and responsible waste management. By following these guidelines, you can demonstrate a commitment to environmental responsibility. Stay proactive in auditing and training processes, and remember that small steps can have a big impact.